TK-004 The Leather Beveler

Design Challenge: The Palosanto Edge Beveler

Many people have asked us about our design and production processes. We worked with our friends at District Leather Supply to develop a handle for one of the prized tools in their lineup, the Palosanto Edge beveler. Through this post, we’re hoping to give you a snapshot into the work that we’re doing everyday.

We first came across this project from our friend Bill at District Leather Supply. Bill approached us about designing the handle for a line of handmade Bevelers, handcrafted by the esteemed artisans known as Palosanto. We can guarantee, each one is a piece of art. While their true passion is metal-smithing, you can see that Palosanto takes great care in everything that they do, their handle are as beautiful as the blades themselves. You should check out this great interview with the creator, Tae Kono Kim.

While tool is beautiful in itself, Palosanto is known for their blades, both exceptionally sharp and durable. In my reasearch it seems that leatherworkers across the globe covet their tools, so it was a true honor for us to be offered this design project!

WHAT IS AN EDGE BEVELER?

For those who are foreign to leather tools, (that included us!) an Edge Beveler is what it sounds like: a tool used to finish the edges of the leather, a discrete detail that we had never really thought about before. In actuality, you can look at any highly crafted leather products and you will see just how important this tool is!

Where to start???

FORM FOLLOWS FUNCTION

While a Kiwi has a certain sculptural aesthetic, the shape was actually derived to accommodate the 7 different ways a person might use a knife. It took many, many hand studies and prototypes, through which we were able to a ton of things that could be applied to this project. For one, the length of the knife creates a very important relationship to the hand. In the Kiwi, the length implies a natural relationship to the hand. The end fits loosely in one’s palm and enabling one’s fingertips to find a natural grip.

The simple contours that make up the handle have an intended relationship to the palm, the fingertips, for pushing, for pulling, etc. We took these ideas and began to explore how they might apply.

FORCES AT PLAY

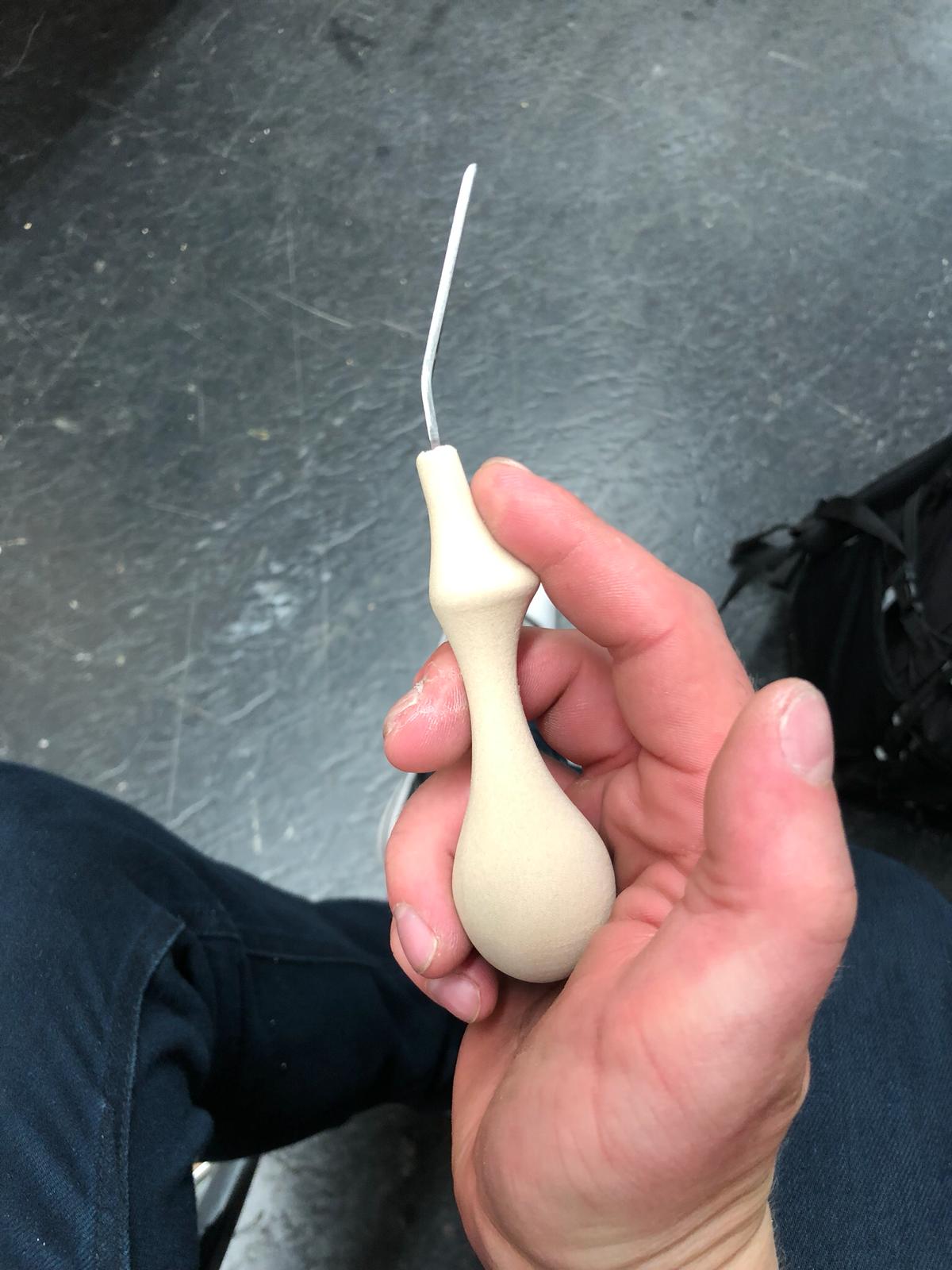

By examining the shape of a tool, you can gather quite a bit of information about how it’s meant to be used. The handle of an Edge Beveler, offers many clues as to how it’s held. The bulbous end is clearly meant to fit snugly in your palm, so that the force applied comes from the arm for consistent, steady movement. The handle then protrudes outward, creating a place for the fingertips for finer motor control. We took these gestures and began to accentuate the form based on the things we’ve learned in the design of the Kiwi.

Fabrication

Modeling in Rhino

Using Rhino, we began to flush out the form. The magic of CAD is that we’re able to not only inspect the fine details, but we can begin to extrapolate a fabrication process as well. Therefore, the handle is designed into two halves, this makes it faster and easier to mill on our CNC router. You’ll also notice that the design is an aggregation of sections, each based on the ergonomic standards applied to the Kiwi.

BUILDING THE CUT FILE

Once the form is found, the model is prepped to be cut on the CNC. The square tabs you see here ensure that the pieces remain secure in the material.

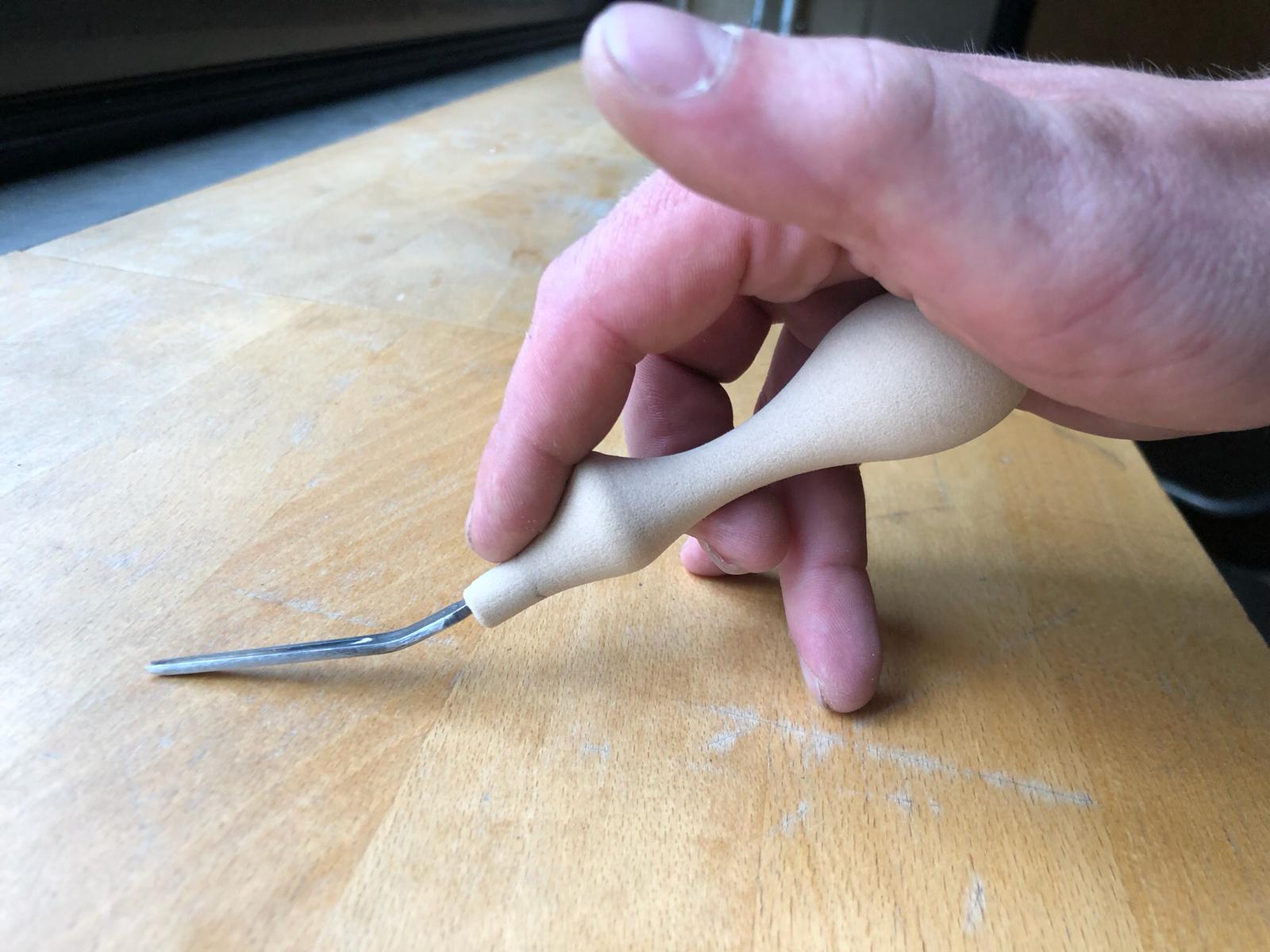

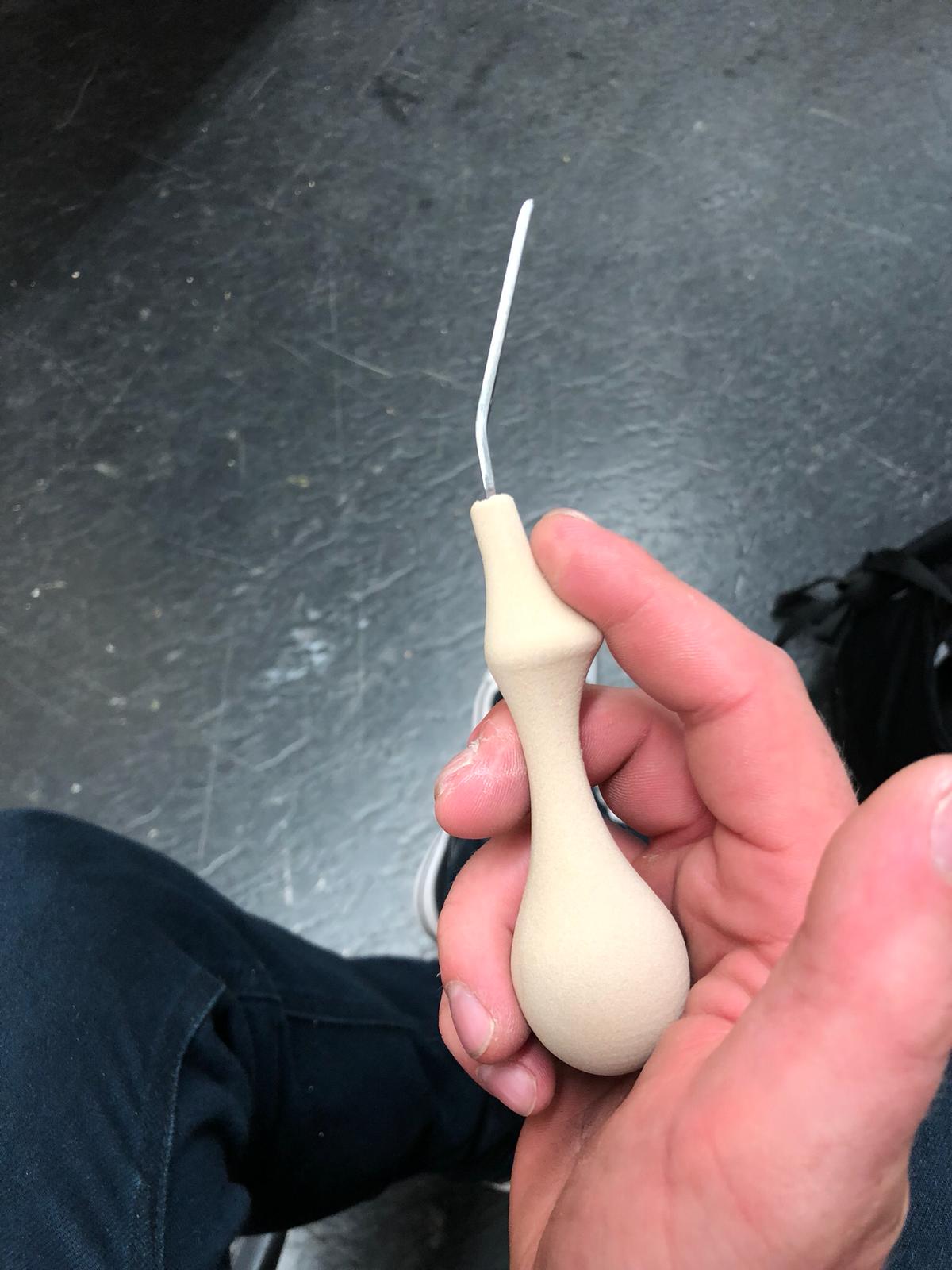

RAPID PROTOTYPING

We’ll usually prototype using high density polyurethane foam. The material can be cut quickly with a very refined surface finish. By using foam, iterative design is much more efficient. To the right is the first test. You’ll notice that although this handle was made in two halves, the seam is virtually invisible. If only all materials were this easy to use!

Throughout Multiple iterations we were able to explore the minutiae of the handle as it relates to the hand. How does it fit in one’s palm? How do your fingertips relate to the curvature of the handle? Ultimately, it was a bit tough to document these changes for this blog.

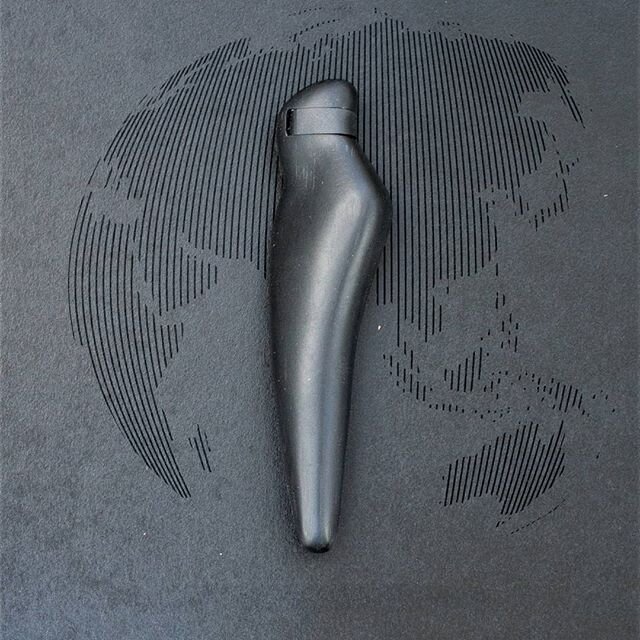

The DESIGN

When you consider the tools that you buy at your local hardware store, it’s important to observe how their form has evolved from the way we use them as a culture. For example, the steel head of a hammer is provides heft and durability, while the tapered shaft is designed to reflect how it should be held. This is something that’s easy to ignore, but incredibly important to the design of a tool. We had the opportunity to objectively define that shape.

The gentle profile of this edge beveler exhibits the precision of its application, the beauty of craftsmanship. Outside of this concept, the form focuses around the two main ways that the tool relates to the hand:

1) The palm grip- Provides the brute force for cutting

2) The finger grip, Offers fine motor control over the blade.

The bulbous end is formed to fit into the palms of a variety of hands,

whereas the exaggerated curvature of the finger grip is meant to offer greater fine motor control.

Asymmetry

By making the design bilaterally a-symmetrical, the knife will never roll out of arm’s reach. Instead, it will remain right in the orientation you left it.

Taking a design and making it beautiful

Final Production

Finally we got to cutting a working prototype. These two are cut from our favorite material, Bocote. It’s an incredibly dense hardwood sourced from Central America offering the perfect combination of strength and sexiness. The perfect material for representing Palosanto craftsmanship.

Hardware

Once the handle is machined, a single piece of hardware is needed. For this sample, we scavenged the ferrule from the sample Palosanto Beveler we had been given. Fits perfectly!

Comparison of original Palosanto handle and our design. From our objective approach, the form still embodies the characteristics that are important to the function of the tool.

Meet the our first edge beveler!

We definitely want to thank Bill for giving us the opportunity to explore this project! We’re still in the prototyping stages for this project but we hope to make them available in the near future! For you Leatherworkers reading this, we’d love to hear your thoughts! We’re hoping to send out a few samples so that we can get better critiques from those of you that use the tools more than we do. If that interests you, just let us know in the comments below!

We’re always up to something! Follow us on our social media for updates and to learn about the new projects we’re working on!